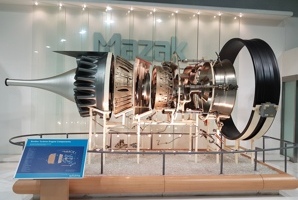

iSmart factory visit at MAZAK

We have recently visited MAZAK factories in Japan,founded by the Yamazaki family. The main topic of EMO exhibition 2017 was INDUSTRY 4.0. iSmart Factory conception has been introduced at the exhibition, we could take a closer look atit in the Oguchi factory. Beside, we have visited the company’s technology center in theMinokamo and Seiko plants, where the multi-taskingmachining centers (INTERGREX), the latest generation of CNCmachining centers and turning centers were introduced including the additive process. We have also visited the Optonics factory, where the laser machines are being produced underground.

The MAZAK factory was established in 1919 by Sadakichi Yamazaki in Nagoya. In the beginning the factory was manufacturing straw mat weaving machines, after changing to industrial woodworking machines, they started producing machine tools, lathes and drilling machines in 1928. This was the basis for the continuous improvement of today’s MAZAK manufacturing company. MAZAK is one of the world’s leading machine tool manufacturers. Approximately 30% of its sales is realized in Europe.

How to plan and carry out an iSmart factory?

MAZAK started its first own flexible production system in 1981, by this time it wasrobots who got the raw material to the machining centers. Between 1983 and 1986 the production developed significantly. The communication between machines was established (m2m), production started using computers, ITsystem was communicating with production in a unilateral way. Bilateral communication was carried into effect in 1998. They managed to develop eFactory in 2006, where production cells were already working on their own and even chuck replacement was carried out by robots. And then came the iSmart factory in 2017.

What is iSmart factory?

MAZAK iSmart Factory is built on three pillars: the SMOOTH Technology, the new SmartBox, which provides faster data analysis beside higher safety; and the MT Connect standard communication protocol. The components are connected to each other in a way that production data can be shared between the production floor and the offices in real-time, which shortens lead time, reduces in-process inventory and lower indirect labourexpenses for manufacturers.SMOOTH Technology, incorporating the world’s fastest CNC and Smooth Process Support factory management software, sits at the heart of Mazak’s Industry 4.0 infrastructure, can be read at Mazak’s webpage. SPS contains software modules that provide the management with useful information. Through functions likemachining program generation, centralized device management, productionscheduling and real-time remote monitoring of the status of the machine, sharing data via network results the highest efficiency for the leaders of the plant or the system. Due to its ability to reduce machining by 30 %, it connects entire machine shops and provide real-time monitoring and analysis capability.

During the one week visit, the Yamazaki family, MAZAK’s CEO Tomohisa Yamazaki, the company’s top management and the Hungarian representatives presented the traditional values too, beside the new technologies, which impressed the visitors from all the countries.

Source: MAZAK MIMTA2017